Yamaha First To Use Eco Aluminium In Japanese Bikes

Yamaha Motor Co., Ltd. has reached an agreement with an aluminium ingot supplier for the procurement of green aluminium. Use of the green aluminium, which is refined using renewable energy, was included in the production of some Yamaha motorcycles from February. Press Release: Yamaha Australia.

This is the first time*¹ green aluminium has been used in Japanese motorcycles, and Yamaha Motor plans to gradually expand its usage into a wider range of applications.

Read more about Yamaha’s eco-initiatives here…

“Green aluminium” is aluminium that is refined using renewable energy sources to emit less CO2 in its manufacture. Aluminium parts account for 12 to 31*² per cent of the total vehicle weight of a motorcycle. Adopting green aluminium is an effective approach for reducing CO₂ emissions from the raw material manufacturing part of a product’s life cycle (falls under Scope 3 Category 1 emissions for supply chains).

Yamaha Motor has reached an agreement with an aluminium ingot supplier for the procurement of green aluminium.

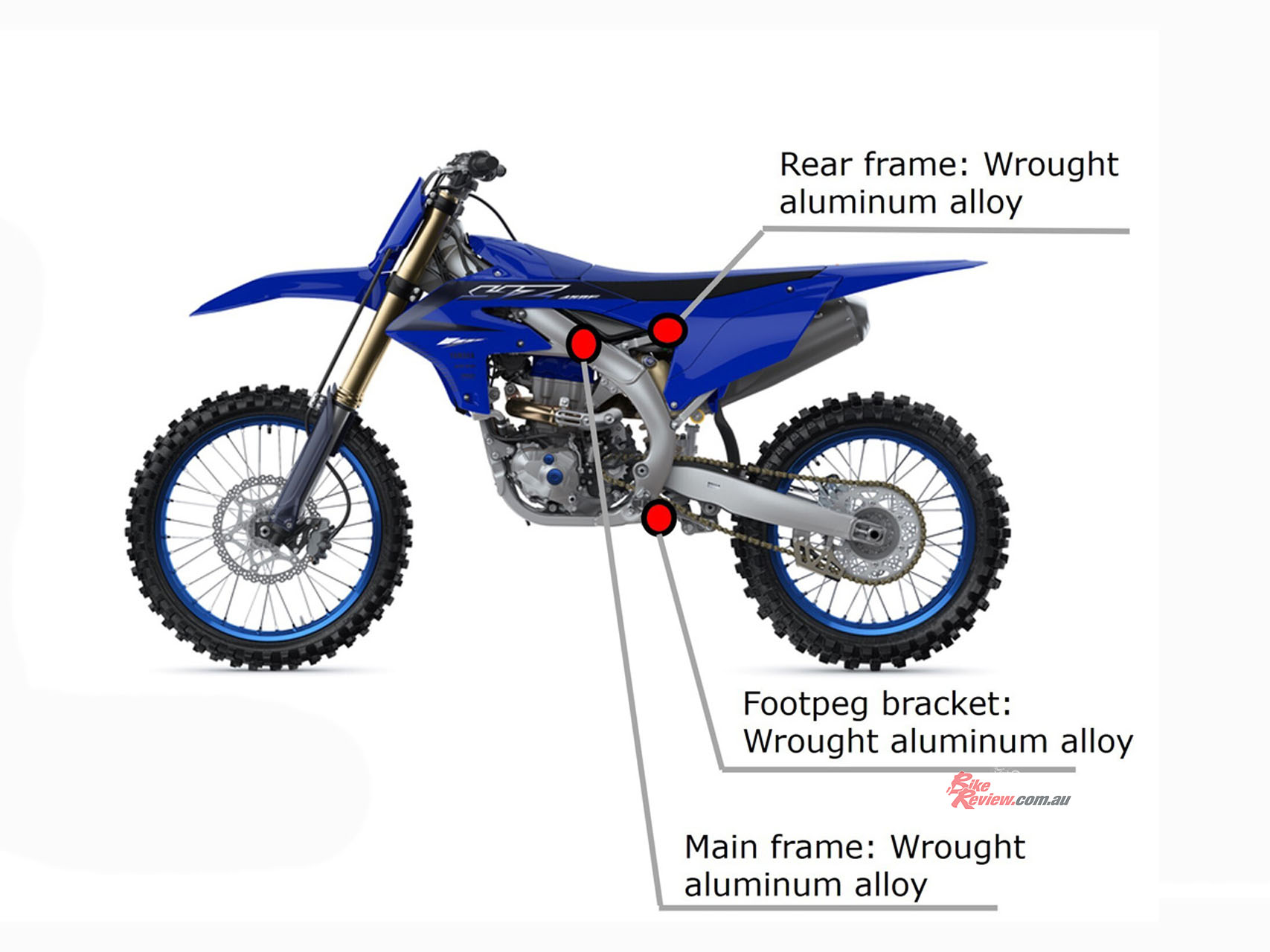

Through the development of its engineering and production technologies and expertise, Yamaha Motor has actively pushed the use of recycled aluminium, which now comprises some 80*³ percent of the Company’s aluminium usage. The introduction of green aluminium is meant to complement this, and will be employed for parts that still cannot be manufactured with recycled materials. As a first step, Yamaha Motor will utilise green aluminium for certain parts in its large-displacement and off-road competition motorcycles, and the company plans to expand the number of models using the material in the future as available supply volumes allow.

In line with the Yamaha Motor Environmental Plan 2050, the Company is aiming to achieve carbon neutrality*⁴ throughout all of its business activities—including its entire supply chain—by 2050. To realise this, the Company has set a goal of switching to 100 per cent sustainable materials by 2050, such as adopting more plant-derived resin materials, developing recyclable polypropylene, and adopting green materials and other recycled materials for its motorcycles.

In line with the Yamaha Motor Environmental Plan 2050, the Company is aiming to achieve carbon neutrality*⁴ throughout all of its business activities—including its entire supply chain—by 2050.

*1: According to Yamaha Motor research, *2: According to Yamaha Motor research in 2022, *3: Calculated based on the amount of raw material used in 2022 at principal Yamaha Motor factories in Japan and overseas, *4: Emissions as a direct result of business activities (Scope 1 and 2) and emissions outside of these (Scope 3).

Editor’s Note: If you are reading this article on any website other than BikeReview.com.au, please report it to BikeReview via our contact page, as it has been stolen or re-published without authority.