Dennis Savic has delivered on his teenage promise to build his own motorcycle – and to prove that Australian manufacturing still has fight left in it. Photos: KB & Savic

From sketching his first prototype in a farfetched teenage dream to leading an international manufacturing team, Savic Motorcycles CEO and creator, Dennis Savic, has built an Australian motorcycle company designing and producing its own electric bikes….

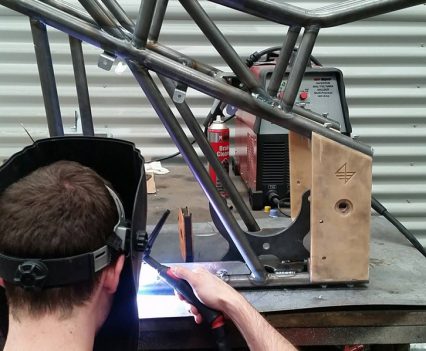

In 2018, Dennis Savic was tinkering on a prototype in the corner of a fabrication shed, convinced that Australia could build its own electric motorcycle. It sounded like a pipedream at the time, maybe even naïve. But today, the company that grew from that borrowed space is delivering the Savic C-Series Alpha to customers, running a West Melbourne assembly line and preparing for global expansion with a Chinese factory partner.

In 2018, Dennis Savic was tinkering on a prototype in the corner of a fabrication shed, convinced that Australia could build its own electric motorcycle. It sounded like a pipedream at the time, maybe even naïve. But today, the company that grew from that borrowed space is delivering the Savic C-Series Alpha to customers, running a West Melbourne assembly line and preparing for global expansion with a Chinese factory partner.

The Alpha marks the first fully homegrown electric performance-oriented motorcycle to reach Australian customers – the product of a start-up that’s spent years balancing design ambition with manufacturing reality. Savic Motorcycles now employs a small but specialised team designing, assembling and delivering bikes from its Melbourne base.

Check out our electric motorcycle and e-Bike section here…

While we spoke, Dennis Savic, now 31, was in Perth visiting family, taking the call from the company’s small showroom there, when his dad dropped by to see what he was working on. “Dad came in and he was just hanging out with me whilst rebuilding one of the bikes. And I said, Dad, did you ever think I would be doing something like this? And he goes, mate, you couldn’t even pick up a screwdriver when you were,” he grins.

Read our Savic C-Series review here…

That moment sums up how far things have come since the days of borrowed welders and night-time experiments. His parents, once wary of their son’s obsession, live just down the road from the company’s Perth-based showroom. The pair came to Australia from Bosnia in their 30s, leaving behind a socialist system and starting over with nothing, which makes their pride in his work all the more tangible. “They’re incredibly proud, you know, about what we’ve done,” he says. “It’s something I learned from them was just to never give up.” That persistence has carried him from backyard fabricator to manufacturer. “We’ve overcome so many impossible things that everything else will come.”

Between those early prototype days and today’s production lay a maze of obstacles. “It’s so multifaceted. I think raising money is a big one, supply-chain evolution has been challenging, and we actually didn’t realise how much we were pushing the limits of the technology that we’re actually using.”

From building their own motor and battery systems to managing suppliers who’d never worked at such small volumes, Savic’s small team had to learn everything from the ground up. Some suppliers vanished with deposits, frames came back out of tolerance and the team went through three complete redesigns of the battery pack and cell configuration. But what really pushed them was integration.

“One of the hardest things to do in this industry is to bring all the different components together into a single unit that works and works well,” Savic says. “Even the large OEMs struggle with that.” The small Australian outfit ended up developing its own motor, battery and control systems in-house – work that global manufacturers typically outsource – and doing it with a team of fewer than 20.

“One of the hardest things to do is to bring all the components together into a single unit that works well – even the large OEMs struggle with that”

Each challenge forced a rethink of how a young company could deliver world-class performance without the resources of its competitors. What looked like setbacks were really steep lessons in engineering, supply chain and survival. “It’s been great. I’ve learned how to lead people and about finance and about brand and about engineering and supply chains,” he says. Those lessons reshaped the company as much as the bike.

By 2023, those lessons were paying off. The company had proved it could design and integrate its own systems, but scaling up required new thinking. The home-grown approach that defined the early years wasn’t enough once production volumes grew and the need for consistent component supply became critical. Savic began looking beyond Australia for partners who could match his standards and his pace.

One of the biggest changes came in where Savic looked for manufacturing partners. In 2018 when I spent time with Savic in his rented corner of a larger warehouse, he championed Taiwan; by 2025, his view had shifted. “There’s so much negative media about China. And it’s like where we’re setting up our factory is covered in forest and it’s super green. It’s like coastal and the seafood is incredible.”

The decision wasn’t only about cost – it was about scale, consistency and the long-term future of the business. “We were dealing with suppliers who couldn’t grow with us,” he says. “You can’t run a proper production system when your parts come from ten different places at inconsistent quality.”

“You can’t run a proper production system when your parts come from ten different places at inconsistent quality”

The move underpinned the company’s next stage. Partnering with an experienced Chinese manufacturer meant tighter process control, the ability to scale from small runs to mass production, and access to financial support that simply didn’t exist at home. “You will not get that in Australia by any stretch of the imagination.”

The C-Series ABS system was developed in conjunction with Bosch Australia

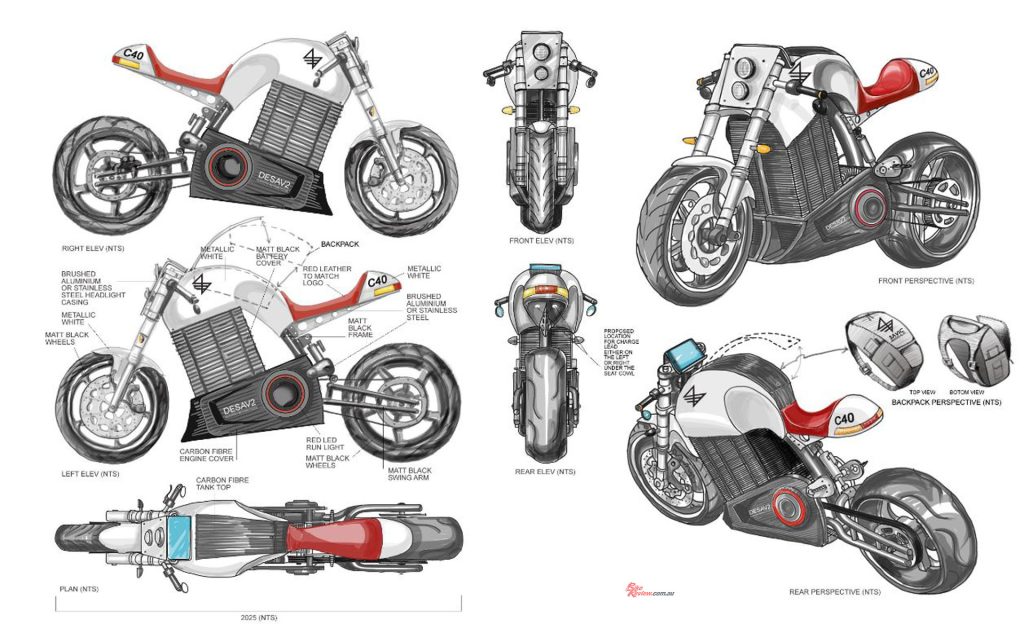

The new arrangement lets Savic’s team focus on what they do best – design, development and final assembly – while the factory handles sub-assembly and component production. It’s a step that moves the brand from boutique start-up to genuine manufacturer, without losing its Australian identity. The result of that persistence is the Savic C-Series Alpha – a 280kg café racer producing 60kW and more than 200Nm of torque. The first production bikes rolled out earlier this year, closing a chapter that stretched longer than anyone expected.

One of its most distinctive features is the single-sided swingarm, developed entirely in-house. It went through three iterations before the team achieved the right tolerances and strength balance. “Having a single-sided swingarm was important for us,” Savic says. “But it’s hard to do, you know… But we got there. It was through sheer persistence we got there.” The result is not only a design signature but a technical milestone for a start-up building its own hardware from the ground up.

Savic originally planned a three-model line-up, the entry-level Omega, the mid-tier Delta and the flagship Alpha, all sharing the same frame. But as preorders rolled in, the message from customers was abundantly clear. “The Alpha [accounted for] 80 to 90 per cent of the orders coming in,” he says.

“A single-sided swingarm is hard to do, you know… But we got there. It was through sheer persistence we got there”

Rather than stretch his team thin chasing low-volume variants, Savic made the pragmatic call to focus on the Alpha alone. It was a smart and mature move by the young Aussie, who has had to balance determination and sheer persistence, with being able to realistically read and respond to the market’s wishes. The high-performance Alpha had captured the public’s imagination and, with limited resources, he chose to double down where the demand was.

Deliveries are now occurring, but Savic doesn’t hide how hard-won that stability was. The company’s earliest customers placed their faith – and deposits – in a product still evolving through design, certification and supply upheaval. “We’ve had to unfortunately disappoint some preorders … because the reality over the last seven years is, like, you don’t know what you don’t know,” he said, adding that honesty was non-negotiable. “We just kept people updated. We didn’t hide anything. Some waited, some wanted refunds and that’s fair. We were honest about it.”

My own test ride confirmed how far the bike – and the brand – have come: torque that’s instantly addictive, high-quality suspension tuned with Aussie racer Jed Metcher’s input and finish quality that on the whole feels production-ready rather than experimental. For Savic, the biggest transformation isn’t the motorcycle but the company around it. “One of the things that I’m proudest of outside the product is just the people we’ve got and the culture that we’ve got brewing in the business.”

He now leads a senior team drawn from some of the world’s most respected engineering and manufacturing firms – PACCAR, Allianz, McLaren and Rolls-Royce among them. PACCAR builds Kenworth, Peterbilt and DAF trucks; Allianz brings heavyweight finance and risk management expertise; McLaren and Rolls-Royce add world-class engineering and manufacturing pedigree.

For a founder who once soldered battery packs by hand, surrounding himself with people of that calibre marks a major shift. It’s allowed him to step back from the bench and focus on leadership, vision and long-term growth. “I’ve put everything on the line multiple times. It gets harder as you get older, because now I’ve got a family and you still do it, you know,” he says. “It’s costing us money for me to do this, and so you think, is it worth it? And I speak to my wife about it, check in with her and see what she thinks. And, you know, we’ve come this far, we’re not quitting now.”

The top-spec carbon C-Series Alpha is proof that anything’s possible with self-belief and determination

He says the pressure hasn’t eased, rather it’s just changed shape. “There’s always something new to solve, but that’s part of it. You have to love the building, not just the result.” Yet the payoff is tangible every time a customer swings a leg over one of his bikes. “People come off the bike smiling … that’s what makes everything worth it.”

“We want to keep assembling vehicles in Australia for Australia”

Savic’s next challenge is growth without losing control. “We’re basically consolidating them, assembling them there and then shipping them as a single unit to Australia just to really increase efficiency,” he says of the company’s new facility in Taizhou, south of Shanghai. “Plus, there’s also shipping compliance that that subassembly really assists with. So that’ll be the stage one of that factory and then stage two will be fully assembled vehicles for the European markets.”

To be clear, Australia remains the brand’s manufacturing base. “We want to keep assembling vehicles in Australia for Australia,” he says. “We’re not going to be importing fully assembled vehicles into Australia. We will be pre-assembling powertrain units in our Chinese factory, and then the frames, the brakes, the body, the badging, all the other detail, the bolts onto that powertrain will be done locally in Melbourne.”

The iconic tunnel leading onto Melbourne’s Bolte Bridge makes a fitting backdrop to the finished C-Series Alpha

That hybrid approach – global subassembly paired with local finishing – supports Savic’s goal of maintaining control over quality and brand identity while improving cost efficiency and logistics. It also reflects how he’s chosen to grow: deliberately, without surrendering independence. That same thinking shapes the business model. Savic sells direct to customers rather than through dealerships, with every order placed online.

“Our margins should be market-leading. But we’ve got to prove that, and selling direct to consumer is hard. And that’s why it’s usually outsourced”

“All of our orders so far have come through online,” he says. The approach cuts out middlemen and helps explain how the Savic C-Series Alpha is priced at a relatively affordable $29,990 ride-away. For context, the Zero SR/F offers slightly more power and faster charging for around $40,000, while the now-defunct Energica EsseEsse9+ sold for north of $45,000. The Alpha delivers comparable real-world performance, more torque than either, and a uniquely Australian design that’s still assembled in Oz.

He’s frank about the challenges that come with doing things differently. “Our business at the end of the day still is, you know, a thesis,” he says. “We still need to go out and prove the belief that we have, and the reasoning that we have, because we’re direct to consumer and we manufacture and design ourselves. So, because we’re doing all of that in-house, our margins should be market-leading. But we’ve got to prove that, and selling direct to consumer is hard. And that’s why it’s usually outsourced.”

That model means his future ‘retail outlets’ will look nothing like traditional dealerships. “We’ve got over 12 months’ worth of production in our order book already,” he says. “And our goal in five years is to be at a production rate of five to six thousand units a year – anywhere from 15 to 22 retail outlets across Australia and Europe – and a nicely profitable operation that works.”

Ask Savic if riders are ready to swap petrol for electrons and he smiles. “I do believe the concept that says people don’t want to convert from petrol to electric is a myth.” For him, the turning point is always the ride. For some reason people think quiet’s bad. But when I ride our bike I realise quiet is awesome!” he says. Over the past year the company has run more than sixty public test rides around the country. “All the feedback’s been incredible.”

From sketching his first prototype in a borrowed shed to leading an international manufacturing team, Savic has built something rare — an Australian motorcycle company designing and producing its own electric bikes in an industry dominated by century-old giants. He’s navigated setbacks, scepticism and start-up survival, yet stayed grounded in the same belief that started it all: that world-class innovation can happen right here.

Dennis has surrounded himself with clever humans and has played the long game to produce the C-Series Alpha

He’s still doing what he set out to do as a teenager – designing bikes, building a team and proving that Australian ideas can go the distance. Every delivery that rolls out of West Melbourne is proof that he never stopped believing it could be done.