Zane headed out to the new Norton factory in Solihull, U.K. Check out how the brand is rebuilding following administration and revival under the acquisition from TVS Motors in 2020...

Norton’s recent history has been an extremely rocky one for the British marque. Essentially revived from the rubble by Indian motorcycle giant TVS, they’re on the road to recovery. I got the chance to tour their new Solihull factory just outside Birmingham, U.K.

Norton’s recent history has been an extremely rocky one. Essentially revived from the rubble by India motorcycle giant TVS, they’re on the road to recovery. I got the chance to tour the new Norton factory in Solihull, just outside Birmingham.

Finding myself in Birmingham is like saying to U.K. locals that you somehow found yourself in Geelong. It’s an industrial area that really doesn’t have a lot going on for the common folk, and it’s certainly not a tourist destination.

Check out my quick test of the 2023 Commando 961 SP here…

But this area has some of the most densely populated motorcycle heritage I’ve ever heard of. The surrounding areas of Birmingham really bred innovation within pre and post-war motorcycle manufacturing. The midlands saw iconic brands like Vincent, Triumph, Royal Enfield, Norton, BSA, Brough Superior, Ariel, etc. I could go on forever here.

Norton represents one of my first loves when it comes to two wheels. The first time I saw the Norton F1 JPS, I couldn’t believe my eyes and ears. This incredibly unique motorcycle made my heart race, and from there, I fell in love with the brand. Ironically, the JPS livery kickstarted a smoking habit later in my life. I’m sure if I didn’t know about Marlboro or JPS when I asked for a packet of cigarettes for the first time when I was 15, I’d probably never have smoked.

Zane had the extraordinarily lucky experience to ride some of the first bikes out of the TVS Norton ownership.

And so the opportunity arose for me to visit the multi-million Pound brand new building that TVS have built for the Norton brand out in Solihull. Just a mildly long train, bus, and walk from Birmingham, I arrive at the pearly gates of Norton. The bustling, large new factory shows no signs that it’s just come out of the rubble of previous ownership.

Walking up to the front doors, there’s a plethora of Norton Commando 961 SPs and CRs lined up out the front, a personal favourite of mine in terms of looks. I was booked into riding one of these later in the day; you can check out my quick test on the SP here…

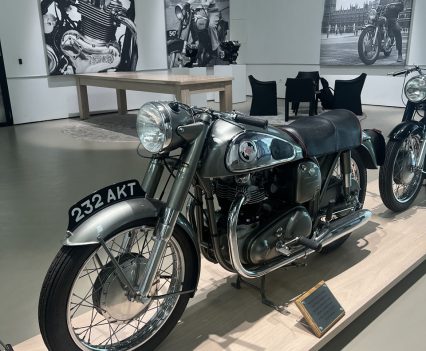

Some of the rarest and coolest Norton’s ever are on display in the reception of the new Solihull factory.

Not yet open to the public, you open the doors to an operation running at full scale with some of the rarest Nortons on rotation in the reception room. Tucked away in the corner is a Norton Energrette, the most important bike in the room as it’s the first ever Norton model built. In seriously beautiful condition, the machine gave me an opportunity to show just how far technology has advanced since 1902.

On a constant rotation in the middle of the room are motorcycles purchased from Ian Loram’s personal collection. This die-hard Norton fan devoted many years to his life collecting the full suite of motorcycles from the British marque. A Dominator, an ES2 and a modern-day V4SV dress the floor for an already stunning display, and I’ve only just walked in the door! Up in the other corner is the V4 café racer displayed at EICMA last year.

My tour guide for the day happens to be John Hogan, editor of SuperBike.co.uk and now Norton’s head of Marketing and Comms. This name is significantly important due to Hogan’s role in his expose of the Norton brand when it was under the ownership of Stuart Garner. I highly recommend giving it a read here. You will be able to read more about the brand in a future interview I did with John, but one of the main takeaways I received from our chat was that he’s looking to start fresh with the brand but build upon its heritage.

Check out Cathcart’s interview with the new Norton CCO…

“When I was writing my story on Norton, I had grown men calling me on the phone in tears as they told me their story about spending tens of thousands of pounds on a motorcycle only never to see it again after it went in for warranty… We want nothing to do with Garner now, and if I saw him at the front gates, I wouldn’t come to work at all.”

So how has the company recovered after being brought from the dust by TVS? Well, it’s certainly alive and well.

So how has the company recovered after being brought from the dust by TVS? Well, it’s certainly alive and well. There’s always a certain level of caution to be had when asking for a factory tour. I often feel at media events we aren’t getting the whole and un-staged experience. But this one-on-one tour provided a complete insight into an actual working day at Norton, with no hidden parts, just a lot of warning to not take photos of certain things.

Walking into the factory, you’re met with state-of-the-art equipment and brand-new everything. The tour actually began at the end of the line inspection. Since these motorcycles go through a special scheme in the U.K., they’re subject to essentially what would be an ADR approval at the end of the line.

Norton is looking alive and well under the acquisition from TVS for £16 million and millions spent on the new factory.

We make our way to the R&D rooms, where a lot of secrecy is being held. The testing of major and minute parts is all done within these rooms: 3D scanners, 3D printing machines, and computers with maths equations on them that my supple mind can barely comprehend.

Down the line, we are met with the engine construction plant. This essentially sealed-off room houses where the hearts of these motorcycles are pieced together. The room is designed to be set at a specific climate, and all the air is processed through multiple filters to ensure it remains dust-free. A big step up from some of the factory lines you see in less-premium brands.

All the components go through an ultrasonic wash system to ensure they’re free of any microscopic particles that have been left behind in the manufacturing process. Then the engine builders assemble the engines with an “intelligent tooling system”, which helps get accurate torque specs and minimises human error greatly. The sealed engines then get processed out of the room, ready to be placed in one of those spectacular frames.

The engine builders assemble the engines with an “intelligent tooling system”, which helps get accurate torque specs.

Running through the rooms up the back, we pass more R&D spaces that actually have bikes from all the major brands in there. I don’t doubt that they have these things in pieces to try and gain some inspiration like all major brands do.

In the corner of my eye, I spot the electric development room. I wasn’t allowed to sneak any photos in there, but what I can say is Norton is in full swing with producing the next generation of EV machines. I did touch on the possibility of bio-fuels with John, but Norton is more looking to develop an EV for day-to-day purposes while allowing riders to enjoy an ICE Norton on the weekend.

From here, we make our way to the crown jewels of Norton’s manufacturing, the hand-welded frame. Here, I had the opportunity to take photos of a few finished frames and see some rejected ones. The process that goes through approving these frames is insane. The rejected frames had imperfections that were simply impossible to see via the naked eye. Sure, a machine will most likely get it right every single time, but nothing can replace the artwork of a tig weld laid down by hand. That’s why you pay the big bucks for these motorcycles.

The last stage of our tour was the assembly line. I expected to see a male-dominated environment here, but there were people of all ages and backgrounds painstakingly assembling these beautiful motorcycles by hand.

The last stage of our tour was the assembly line. I expected to see a male-dominated environment here, but there were people of all ages and backgrounds painstakingly assembling these beautiful motorcycles by hand.

The biggest takeaway from this stage has to be the rate at which they were actually assembling the motorcycles. There was no rush and no urgency to just throw a part on and torque it down. Everything is placed with care and consideration as if they were building a motorcycle for themselves.

Production is still relatively slow, being scaled to 8000 motorcycles a year. This is not something I expected to hear from a brand owned by such a major motorcycle empire such as TVS, who can pump out up to 14,000 motorcycles a day. Time efficiency is not in mind here at Norton; it’s all about producing some of the most beautiful hand-built motorcycles in the world, and they succeeding.

Production is still relatively slow, being scaled to 8000 motorcycles a year. This is not something I expected to hear from a brand owned by such a major motorcycle empire such as TVS, who can pump out up to 14,000 motorcycles a day.

Just as I thought the tour was over, John took me to another building packed to the brim with classic Nortons. While I was not allowed to photograph anything inside the building, the plan for John is to work with this massive collection of ultra-special motorcycles to get the brand back in touch with its heritage. When I say I wish you could see what my eyes saw, I mean it. There had to be at least one bike of every Norton model ever made…

The only problem is if you want one, you’ll probably be waiting for six months after your order. The “heritage” customers that came from the Garner era were actually ruled never to receive their motorcycles. TVS, under zero legal obligation, decided to make these motorcycles and really win back trust in the brand. Norton should be on track to relieve all outstanding orders on motorcycles purchased prior to liquidation by the end of the year. There’s currently no opportunity to purchase these bikes off a Norton showroom floor; they’re still very much made to order.

There’s currently no opportunity to purchase these bikes off a Norton showroom floor; they’re still made to order.

For those in Australia wondering when we will see the brand on our shores, well, there’s also no set date for that either. Norton is planning to hit the North American market first but will keep the Oceanic region heavily in mind for the future.

And so that brought our tour to an end. I’ve done a few car and motorcycle factory tours in my time and nothing comes close to true hand-built like Norton does. I’ve gained a massive appreciation for the work that has been put into a brand that is so close to the hearts of many people internationally.

In a world where you buy a bike wearing a European badge that has been sheepishly produced overseas, we have Norton, who is proudly waving the Union Jack. I pray they bring these motorcycles to Australia once again…

The Solihull production plant squashed any fear I had of TVS moving the production to another country to lower production costs. In a world where you buy a bike wearing a European badge that has been sheepishly produced overseas, we have Norton, who is proudly waving the Union Jack. I pray they bring these motorcycles to Australia once again…

Editor’s Note: If you are reading this article on any website other than BikeReview.com.au, please report it to BikeReview via our contact page, as it has been stolen or re-published without authority.