Neil Adams took on this unfinished Spondon TL1000 bitsa and created a finished and fast masterpiece... Words & Photography: Dave MDM Manning

Although Spondon Engineering was subsumed into the doomed Norton motorcycles back in 2008, for most motorcyclists the memory that they have of the Derbyshire engineering firm was the stunning tubular aluminium frames that they made for road and race bikes.

The company, ran by Bob Stevenson and Stuart Tiller, had begun by making steel-framed chassis for race bikes during the ’70s and early ’80s, although the demand soon grew for road-going frames for the likes of Japanese inline fours such as Suzuki and Kawasaki motors, with tubular aluminium frames soon taking precedent over the steel Reynolds tubing and a number of frames also being built with triple section aluminium extrusions.

It’s the tubular alloy frames, made with 7020 grade round tube (and invariably highly polished) that people think of whenever you mention Spondon, and the Suzuki TL1000 that you see here is housed in one of what is thought to be just five Spondon frames made for the big Suzuki V-twin.

“The bike was delivered to Neil Adams at Made In Metal, with the requirement that he finish the bike to his usual exacting standards for the current owner.”

The full history of when and for whom this particular frame was made is grey, but what we do know is that a complete bike was delivered to Neil Adams at Made In Metal, with the requirement that he finish the bike to his usual exacting standards for the current owner.

The original Spondon frame kits were supplied with a fuel tank, sub-frame, an Öhlins rear shock and a set of Spondon manufactured rearsets and fork yokes. This frame had the full options list, including the Öhlins steering damper.

The Spondon frame definitely doesn’t blend in with anything else on the road, combined with the Metallic blue paint.

Aside from the kit, the bike also had a breathed-upon Suzuki TL1000S engine, a single-sided Spondon swingarm (the frame kits could be specified with single or dual-sided arms, or the original bike’s fitment if the budget was tight), a set of KTM forks, Brembo brakes and a pair of magnesium wheels.

The rear end was moulded to perfection with its aggressive tall tail, all made out of metal not fibre-glass.

Neil’s brief was to sort out a tail unit, address the fact that the fuel tank sat a little high, and essentially get the bike fully prepped and up and running and ready for use.The tank that came with the bike was not only too tall, but also a little on the thin side and thus easily dented.

Check out our other custom bike features here…

Neil cut off the top of the tank – with the original Spondon filler cap – and then remade the rest of it from 2mm alloy sheet. This required the standard Suzuki airbox to be removed, and replaced with pancake style air filters. While this resulted in a loss of power, it perhaps equated to a maximum of a 5hp loss, and that is somewhat irrelevant in a bike that weighs significantly less than the original.

Neil continued working with 2mm aluminium for the tail unit, creating a smooth, minimalist tail, complete with undertray that matches the lines of the tank with subtle hints of Honda RS250 GP bike. It was actually made to replicate the shape of a fibreglass seat unit that the owner had.

The tank and tail were formed with muscle, hammer and an English wheel. The rear sub-frame had originally sat about 15cm higher than it does now, but Neil modified it so that it sits lower and the top of the tail is now inline with the fuel tank.

The custom made titanium full exhaust system came with the bike – the owner told Neil it was made by an aircraft engineer – and was very well made but sat a little too close to the engine, so it was tweaked a little by slicing a few millimetres here and adding it elsewhere.

It barely needed moving to be fair, but Neil thought it better to do it as its all mounted with springs and had a possibility to move the wrong way a little and touch the swingarm.

The custom made titanium exhaust system came with the bike, the owner told Neil it was made by an aircraft engineer.

The bike came to Made In Metal loosely bolted together, and all the little bits that actually make the bike work had been left to do. Consequently, Neil stripped the bike completely to paint the engine black and check everything else was in order in the process, although this did uncover a few anomalies that needed to be sorted to allow the bike to perform as it should.

“As soon as you open the throttle everything just hooks up and works really well. I found myself picking the bike up mid corner quite often until figured out actually how late you can tip it in and still easily make the corner – it rides like nothing I’ve ever ridden before”…

The wiring loom, the coolant and oil cooler hosing, various linkages and the brakes all needed to be sorted out and plumbed up, in doing so, it appeared that at some point in its previous life, the water pump casing and clutch cover had been modified to take an extra water pipe and oil pipe.

After some discussion with the UK’s premier TL expert, Sam Matthewman, the conclusion was that the modifications had been made for forced induction of some form. Neil replaced the casing with a standard one as the other inlet\outlets weren’t needed.

During this investigation, it became clear that the engine has been stripped at some point, with a big bore kit fitted, although without stripping the motor, it’s unclear as to whether it was to 1040cc or 1080cc – both popular conversions that turn the feisty TL engine into a wheel-waving torque monster.

The actual capacity of the engine is unknown as it had a big bore kit install, but Neil believes it is an 1080cc.

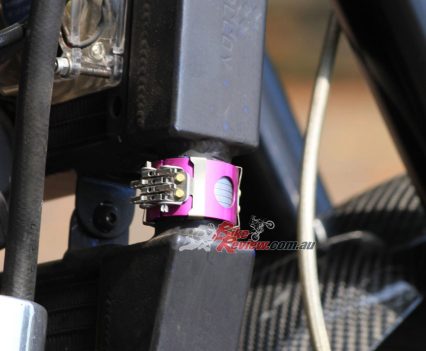

The wiring loom that came with the bike was modified by electrics wizard Geoff Chilton, who worked his magic with some of the issues that Neil had come across, and used momentary switches as opposed to latch switches for an improved operation.

The finishing touches came with a lot of polishing, and an exquisite shade of blue metalflake added to the tank and tail by Rocha Restorations. Having not ridden a Spondon previously, Neil was very surprised as to how quick it turned in, and how unstable it felt unless you were on the power or the brakes. This was partly due to the aggressive rake and short wheelbase (there’s the Spondon race experience showing) and the Öhlins steering damper that made the steering feel notchy even on its lowest setting.

“As soon as you open the throttle everything just hooks up and works really well. I found myself picking the bike up mid corner quite often until figured out actually how late you can tip it in and still easily make the corner – it rides like nothing I’ve ever ridden before, and takes a while to get used to it, but when you do its pretty cool” Neil grinned.

Spondon TL1000 Specifications

Engine: 1996 Suzuki TL1000S, big bore (1080cc or 1040cc, no one really know but it’s not stock), airbox removed & pancake air filters fitted, custom made titanium full system, windowed clutch cover.

Chassis: Spondon bespoke tubular aluminium trellis frame, sub-fame modified to sit lower.

Suspension: KTM RC8R WP forks, Öhlins shock, Spondon Engineering rearsets, IRS controls

Swingarm: Spondon Banana swinging arm, custom Spondon yokes.

Brakes:320mm full floating Brembo discs, radial Brembo calipers, braided stainless steel brake lines.

Wheels: Magnesium alloy wheels.

Bodywork: Spondon fuel tank heavily modified by Made In Metal, carbon fibre RC8R front mudguard, seat handmade from 2mm alloy sheet, handmade alloy tail piece by MIM, custom battery box under the seat hump, custom made electrics box and all hidden under the seat, 5in round headlight, custom LED tail light recessed into seat unit, Oberon bar end LED indicators, blue metal flake paint.

Spondon TL1000 Gallery

March 6, 2021

I’m humbled by the kind words and truly honoured that you guys have taken the time to feature some of my work. It’s a great bike and a real eye opener to ride.

Thanks again guys.

Neil