This custom Laverda Motodd is a Redax Laverda creation and is a case study in doing a custom build the right way, from the ground up... Words & Images by Kris Hodgson

This stunning creation is owned by Mike, a Laverda aficionado and was created by Red from Redax Laverda, featuring a host of bespoke components integrating a Motodd chassis with a heavily modified Lavera 180-degree Series 2 1200 triple.

Having caught up with Red and Mike at the Barry Sheene Festival of Speed, we actually got to see the bike as a work in progress, which helps reveal more about this particular machine, namely a generous use of carbon-fibre.

As is often the case, the story starts back in the ‘70s, when Mike was younger and cast an envious eye over machines which he couldn’t at the time afford, but which were instead added to the ‘one-day’ list.

“I grew up in London not far from where Phil Todd had his shop in Croydon,” Mike explains. “The guys were building specials all over the UK at the time and Motodds were among the best. A few years ago I started collecting the bikes I always wanted but couldn’t afford, and Red had worked on my [Laverda] 3CL and one day just happened to mention he had a new old stock Motodd frame.”

“Once I recovered from the shock I bought it, but without any real idea of how it would turn out. It could have been a disaster but thankfully Red and I saw eye to eye. The philosophy was to upgrade everything that could be, and have nothing on the bike that was unnecessary. And it had to work well!”

Red had the Motodd Mk3 in his possession due to having always wanted to build such a creation saying, “I’ve always wanted to build a custom framed Laverda, using modern suspension, wheels and tyres and the option to buy the Mk3 was convenient at the time. Of all the custom frames that have been built over the years for the Laverda triple engines, the Mk3 Motodd is probably one of the nicest frame kits made.”

The Motodd kit originally included a swingarm, frame and bodywork, with this project starting just with the frame and swingarm

The project unofficially started in 2010 with the collection of parts, including the frame and swingarm kit in the UK, while other bits and bobs came from Fleabay, such as the Multistrada forks and GSX-R rims.

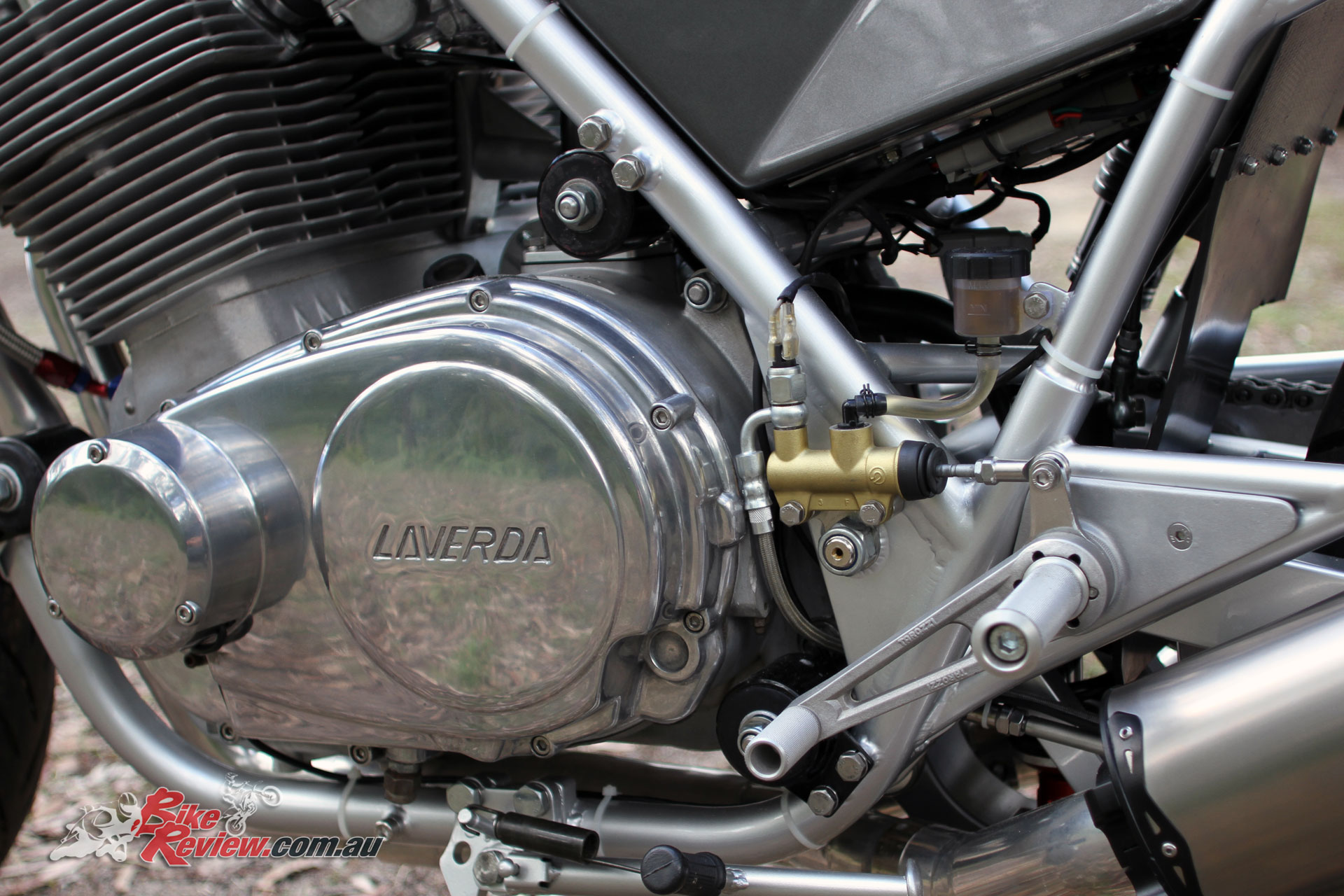

The heart of this machine is the Laverda triple cylinder however, which was sourced from Serbia and is a 1981 Series 2 1200 (four-stroke triple-cylinder) powerplant with a 180 degree crank. The following year would see Laverda switch to a 120 degree crank, which is actually what the Motodd Mk3 was designed to take (and why it includes rubber mounts).

Far from slapping in an old engine, this one has received the Redax treatment, running a bore and stroke of 81 x 74mm, with the capacity a slightly boosted 1145cc, compared to the stock 1117cc. Compression runs at 10.2:1. Standard was 8.0:1 with a 80 x 74mm bore x stroke.

Improvements include a Redax Laverda machined crank, which was re-balanced by Crankshaft Engineering and is a staggering 3kg lighter than standard, with the addition of Carrillo con-rods and custom-made Ross Racing pistons with ceramic and dry film coatings.

These are joined by custom F1 camshafts, blanks machined by Laverdia Scozia in Scotland and a cam profile grind by Newman Cams in the UK, who also made the custom cam bucket followers.

Valves are also custom AV&V items from Canada made to Redax specifications, while the head is ported by OEM in Brisbane, and opened from 32mm to 36mm on the inlets, with custom machined offset and angled inlet manifolds. With the head work done the head and exhaust valves went to Competition Coatings in Brisbane, where the combustion chamber, exhaust ports and exhaust valves ceramic coated.

Red designed and fitted the addition of a oil filter in behind the steering head, which also required a specially designed oil cooler

Now while the Laverda didn’t feature an oil filter, it was a particular request by Mike, with Red putting considerable work into deciding how to install said filter, along with an oil cooler, with the end result looking clean and professional. As you can guess by looking at this bike, the end result being as good as, if not better than manufacturer standard is very much the goal, and one which has been well and truly achieved.

Redax machined the oil filter head, and it is now fitted into the headstock area, with a custom dual pass oil cooler with both fittings on the one side created by ARE Cooling in Brisbane. It’s an amazingly clean installation, with braided oil lines elegantly routed and featuring red and blue fixings.

For fueling Red uses a set of Mikuni RS 36mm Flatslide carburetors, originally fitted to Jap fours, and modified to suit the Laverda three-cylinder, with a custom Hall Effect ignition system mated to a four-channel Ignitech programmable controller, allowing the use of three Nology single pole coils, one per cylinder.

Mikuni RS 36mm Flatslide carburetors are modified from a four-cylinder Japanese machine to suit the triple

Other modifications include the machined primary drive sprockets to save weight, and running a Duplex chain, while the five-speed gearbox now includes a billet fourth gear, due to weaknesses in the standard item on bikes putting out the kind of power the Motodd now boasts.

In the clutch there’s Kevlar lined clutch plates, three standard clutch springs, and three heavy duty clutch springs, with a Redax Laverda billet CNC machined hydraulic clutch cover and Brembo master-cylinder. Final drive is a 530 chain, with a custom rear sprocket designed to suit fitting the GSX-R rims with the Motodd chassis.

A set of custom headers and collector were made by CES Racing Systems to match a Two Brothers Titanium GSX-R600 muffler and are based on the system used on the racing Laverdas, with billet alloy exhaust roses. The end result is light, and offers a distinct look and an even more distinct exhaust note.

Early dyno runs on a Dynotech are showing a healthy 100hp, with more work to be done with more kilometres on the engine, and running premium 98 octane fuel.

As previously mentioned the frame and swingarm is a Motodd kit, of which five variants were made, with this being the third (Mk3). The rubber engine mounts were for the 120 degree crank, which was necessary for the vibrations, while the frame is T45 steel tube. Total production was only around the 50 unit mark, with 12 of those being Mk3s, so these are a very rare beast.

Redax had the Motodd frame modified to remove all the standard brackets removed to keep the lines clean

The frame has been modified, with original tabs and brackets removed, to start from a clean slate, with many of the original Laverda fixings no longer necessary due to the custom nature of this build.

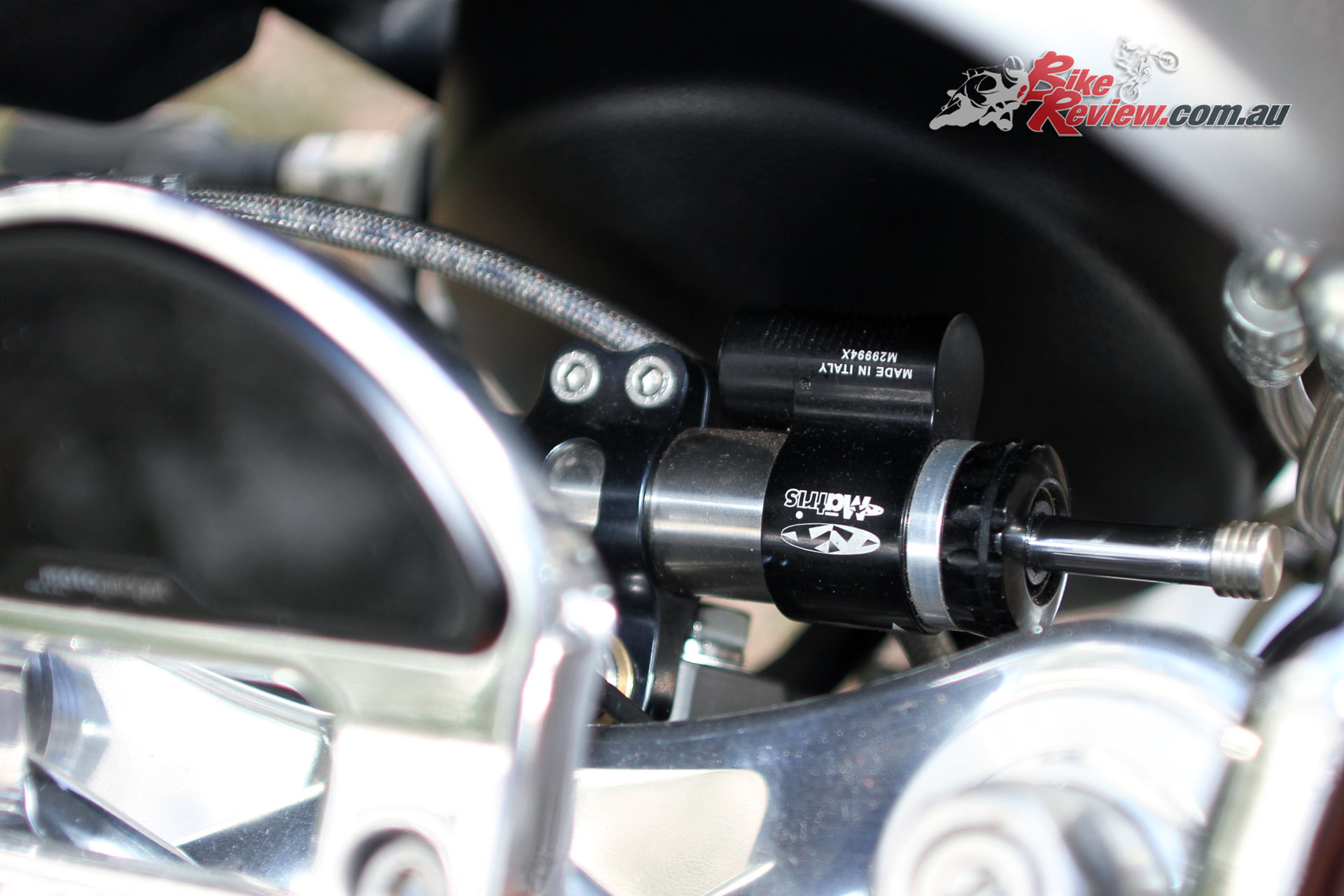

With a set of older Multistrada forks to be used, one-off custom machined triples were required, while the forks were chosen for their close match to the original Laverda Marzocchi units, but now equipped with Racetech springs, and modified shim packs.

This was joined by a set of customised ‘bar risers for standard Laverda Jota handlebars, and incorporating a very trick Moto Gadget dash unit, which is artfully incorporated into the design.

Specially made carriers were used to match the Multistrada calipers to the rotors, with a custom aluminium front guard also used

Due to running GSX-R wheels front and rear, and the Multistrada Brembo calipers on the front requiring a 320mm rotor, a set of custom rotor carriers were machined up, with Ducati 320mm rotors fitted to them by MetalGear Brisbane. The master-cylinders on both ends are actually Ducati 996 units, with Kaneg levers.

The rear brake is a standard GSX-R rotor, with the Brembo caliper on a custom floating caliper mount and torque arm by Redax, not to mention the rear brake master-cylinder mount, which uses the swingarm pivot bolt as a mount. Also custom made for the swingarm are the axle spacers, rear axle, axle adjusters and swingarm link.

The shock is another custom, from MP Suspension in Cape Town, South Africa, as they were the only company of several approached who were able to create a modern spring that would suit the limited dimensions available, so if you’re in a similar situation, look them up!

That’s the majority of the larger items, but the devil is in the details and there’s a serious level of detail on the Laverda Motodd, starting with the carbon-fibre tank, which is actually made by a fellow Aussie Laverda Motodd Mk3 owner, after having to weld the original alloy item that came with the Motodd several times over the years. It matches the styling of the original, but you’d never know it was a carbon-fibre item having been painted. Check out the WIP picture below to see all the bodywork prior to painting.

The carbon-fibre tail unit comes from Serbia, where another Laverda aficionado named Boba resides, and is a Laverda 750 SFC replica, that was modified to suit this bike. Under the seat and nestled within the frame is a carbon-fibre electrical box which slides out for easy access, holding a Lithium battery and the electronics, making for an extremely clean assembly.

The carbon-fibre tank is one of two made by a fellow Motodd owner, this is a WIP shot from the BSFoS in 2016

The comfortable looking seat is from Guzzler Seats in Brisbane and a testament to the fact that Mike will be riding this machine, while being well styled to the overall machine, with that classic minimalist race tail styling.

The paint scheme has been somewhat controversial in the tight knit Laverda community, although I can’t help but feel there’s a little bias involved, with people being convinced how something should look, especially when you’re talking a classic brand.

From a slightly more outside perspective (keeping in mind my Dad is die-hard Laverdite), it’s an awesome paint scheme that adds real depth to the bodywork, with the orange (Lamborghini Orange) chosen to pay homage to the traditional Laverda heritage, and the darker silver on the bodywork (Porsche Charcoal Grey) providing a solid background. A lighter silver is used for pinstriping, and matches the frame, forks, headers and to a lesser extent the aluminium front guard.

The paint scheme on the Motodd is not only of the highest quality, but also a exquisite in person, far more-so than the pictures

The paint scheme on the tank actually deviates from the tank’s natural shape, however the depth in the paint and the design come together to really nail it. A lot is lost in the photographs unfortunately, with patchy light during the shoot, but in the images where the sun was out, you’ll be able to see what I mean. It certainly needs to be seen in person. When we arrived for the Laverda Concours back in 2016 the bike was actually fitted with a set of GSX-R wheels painted in the same charcoal grey as found on the bodywork, with Mike settling on the black wheels as his final choice.

I’m going to be that really annoying guy and say I thought the wheels matching the bodywork in charcoal looked better, however the black wheels do help keep your attention on the heart of this machine – the engine, frame, tank and tail. The paint was done by Wade Lobley of Brisbane Auto Repairs. The frame, swingarm and bodywork are painted in 2-pak, while Roberto’s Custom Powder powder coated the many one-off billet components, not to mention the wheels and rotor carriers.

Other details include a Bosch 7in single headlight, with custom billet mounts, that also incorporate the Rizoma LED indicators on the front end, with the rear pair set into the tail unit. A flyscreen unit from Holehot Performance in the US joins the headlight, helping shade the Moto Gadget Pro-Scope digital display, which is set into the top triple. Standard Nippon Denso switchgear is retained, with the high and low beam switch now controlling the dash.

The ‘bar-end mirrors are actually eBay specials that closely resemble similar offerings from Rizoma, while rearsets are Tarozzi units based off the original Laverda rearsets, and yes that’s left side brakes, right side gear changes.

The GSX-R wheels in black don’t show off the wheel design to the same extent, while the sprockets are machined and lightened

The GSX-R wheels are from a 1987/1988 GSX-R1100, with a 2.75 x 18in front and 4.00 x 18in rear, replacing the Laverda 2.15 x 18in front, and 2.75 x 18in rear. They are shod in Dunlop radial rubber, with a 120/60 – 18 front and 150/70 – 18 rear. The previously mentioned front guard was a custom made alloy unit by Matt (who also extended the seat unit).

The end result speaks for itself, combining a stunning classic marque with the best elements of a custom build, a rare custom frame, plenty of ingenuity and elbow grease, plus plentiful bespoke components, to ensure this bike is a true work of art. How it failed to win the Laverda Concours Best in Show award in 2016 is beyond me, although it did attract a fair amount of silverware on the day.

In fact the results have been so successful that another Laverda Club member sought out a Motodd Mk3, with that now on the books for Red at Redax, along with a few other interesting projects.

“Building the bike has been great,” explained Red, “It’s the first time we have embarked on a bare frame custom build and the experience has taught us a lot. After riding the bike in the shakedown trials I am very sorry that I decided to sell the project to Mike, as if I had built and ridden it first I would never have sold it on. It is by far the nicest Laverda I have ever ridden.”

“We have another Motodd to sort out now but it will not be identical to this build,” added Red, “Apart from the next Motodd, we have three custom made Laverda Spaceframes we have started to build using triple engines. One is going to be road registered and the other two will be race bikes in the BEARS series. Plus we have orders now for three more 880cc Twisted Twins, where we change the crank phase from 360 to 270 degrees.”

Having received the full Redax Laverda treatment the 1200 triple was putting out a modest 100hp during testing, before being tuned for full performance after run-in

Checking with Mike on what his plans for the future are, he admitted, “Ride the Motodd for now, I may tinker with the bars and swap the headlight for a dual unit, but that’ll be down the road. Bikes I’ve hung on to have always evolved. I’m hanging on to this one, so no doubt it’ll change in the years to come.”

As for advice to those looking to do a similar project, Mike added, “If you commission a build, make sure you’re comfortable the builder has the skill and dedicate to do it right. A real one-off custom is going to take longer and cost more than you expect, but done rights it’s worth it. I was lucky to meet Red and see what he is capable of before doing this. I’ve got a couple of other custom bikes but wouldn’t have undertaken something like this with other shops.”

There’s also a long list of special thanks to those involved in various ways with the build, with the Queensland Laverda Club involved, Bruce for wiring up the Moto Gadget M-Unit and Pro-Scope dash, Matt for the seat unit extension, alloy front guard and chain guard, plus Mark for help with design, ideas and general support.

Special mention also goes to Waz the CNC guru who made the one-off custom parts for the build, as well as Rob, the fellow Mk3 Motodd owner who made the custom carbon-fibre tank and bodywork, when he created them for his own Mk3.

Plus of course to Redax Laverda for their work.

You can check out our feature on Redax Laverda here: